Dust Control System

These instructions will take you through the installation of the X-Carve Dust Control System on your X-Carve 3D carving machine. This system comes with an easily detachable dust boot and self-contained hose management system.

Inventory

Tools Required (Not Included)

- 4mm Hex Key

- 3mm Hex Key

- 2mm Hex Key

- 8mm Wrench

- 10mm Wrench

Overview of Parts

In your box, you will find a number of larger parts as well as a smaller box of hardware. You’ll want to look for the following:

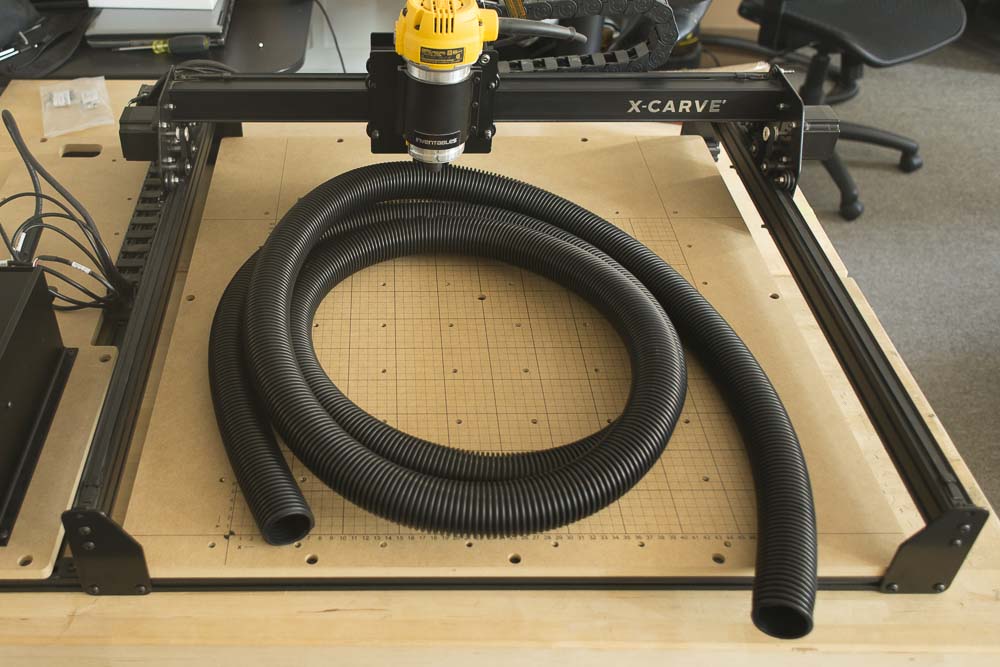

Conductive Hose

This connects the dust shoe to the vacuum. It is conductive and will dissipate static buildup when properly grounded.

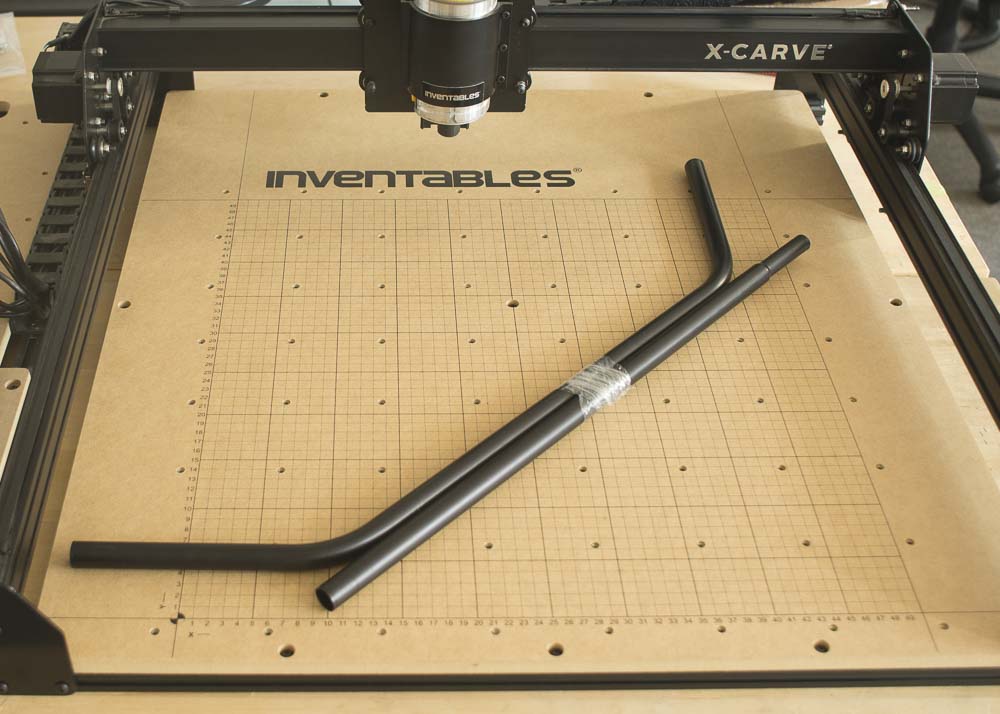

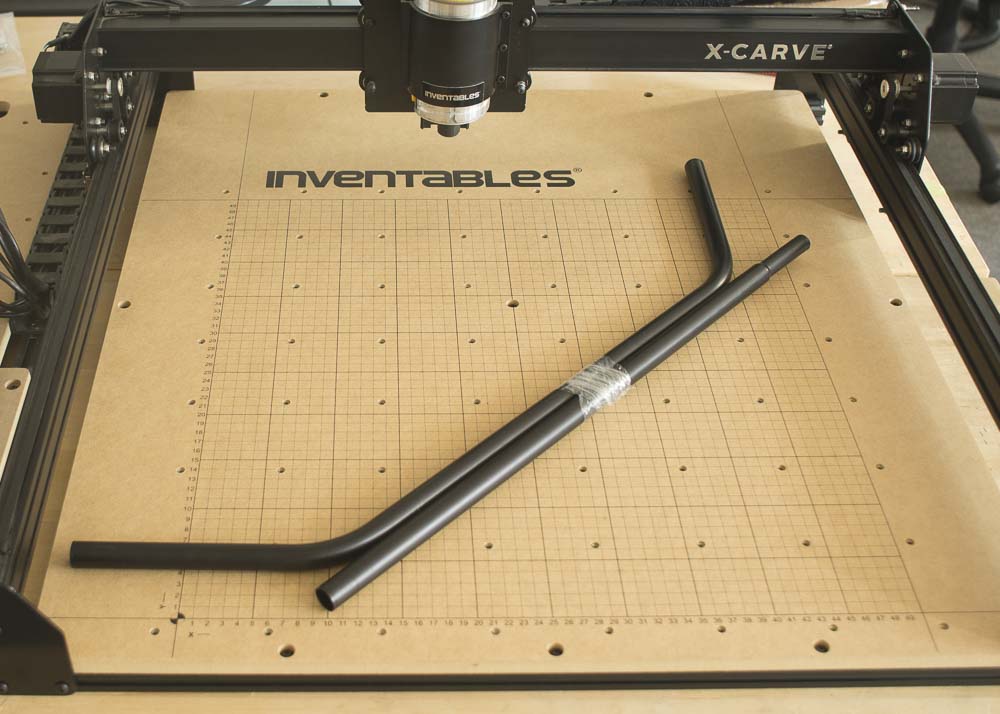

Hose Support Poles

These poles fit together to suspend the hose assembly over the machine. The straight pole is the bottom pole and the pole with the two 45º bends fits on top.

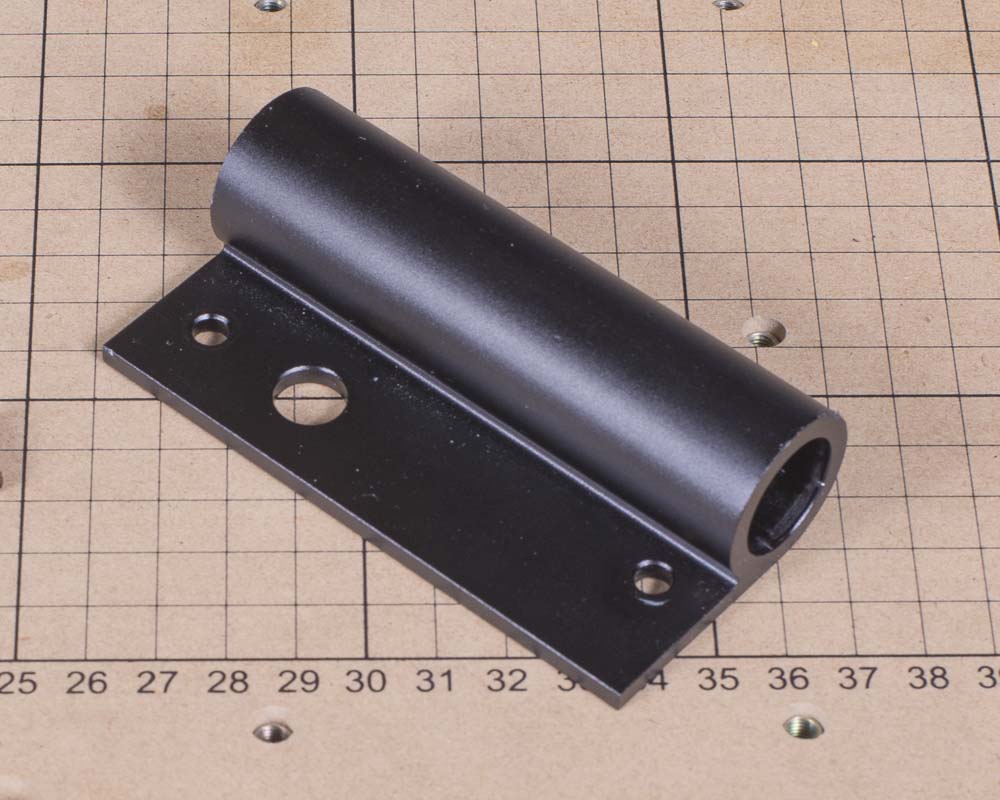

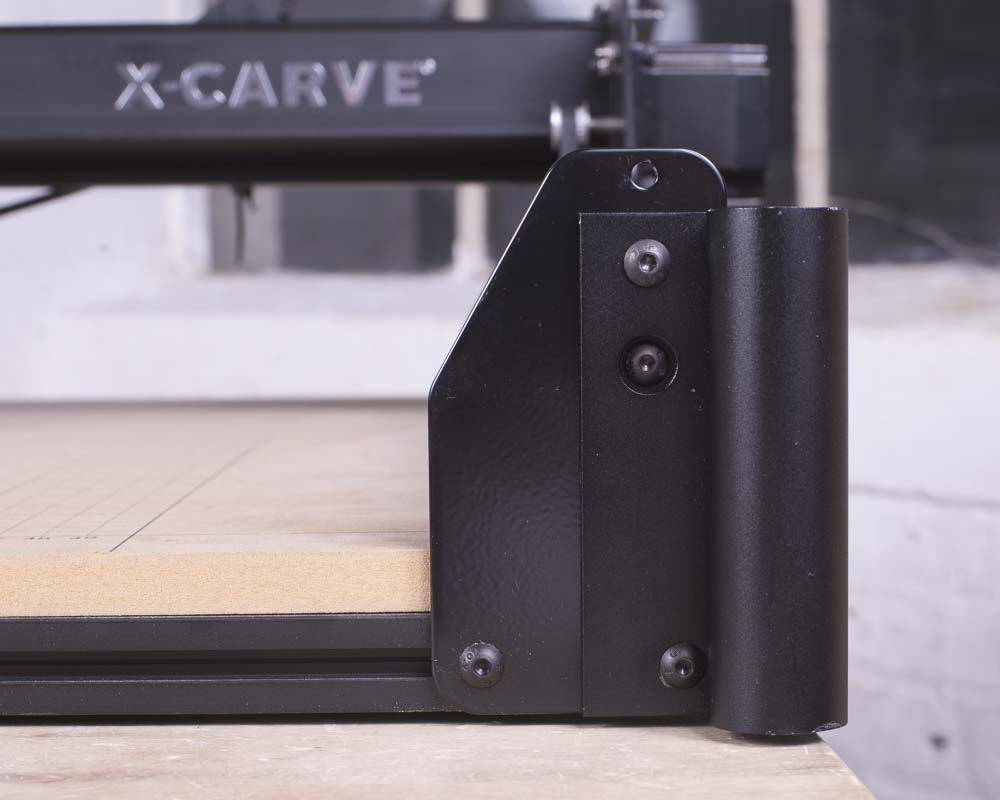

Pole Support Bracket

This bracket mounts onto the right-front makerslide end plate on your machine and holds the bottom pole in place

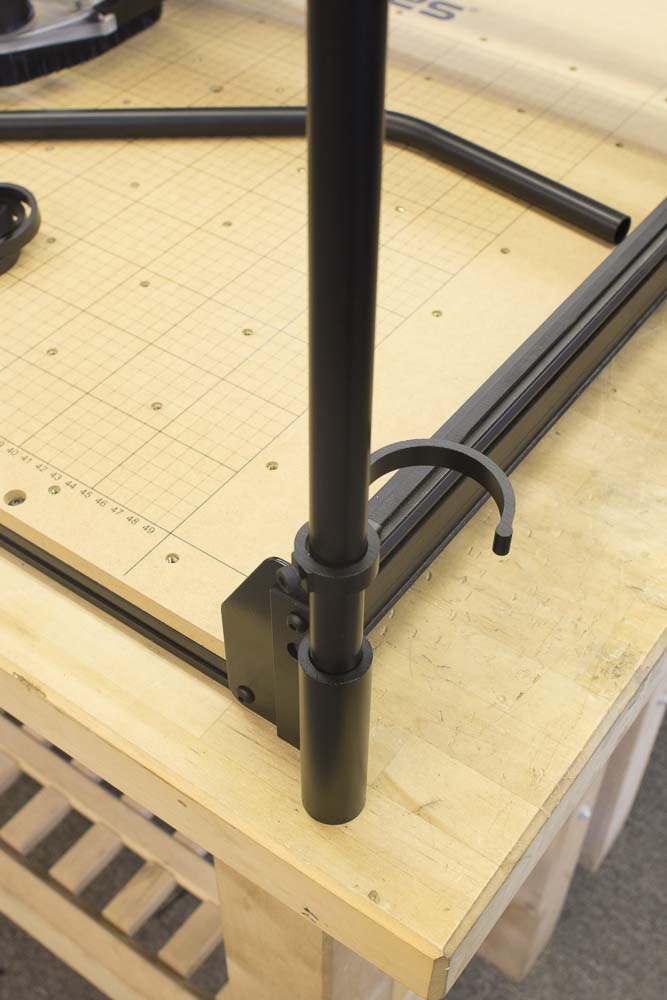

Hose Clips

These mount on the hose support poles to hold the hose in place. Three mount on the top pole and two mount on the bottom pole. The threaded hole in each clip accepts a M5x8mm socket head cap screw to hold it in place. These screws are located in the Support Assembly Hardware Kit.

Support Assembly Kit

This hardware kit includes the necessary components to attach the pole support and the hose clips. It includes:

- M5x8mm Socket Head Cap Screws (5x)

- M5x12mm Button Head Cap Screw (1x)

- M5x16mm Button Head Cap Screw (1x)

Grounding Kit

To prevent build-up of static during dust collection, your kit includes a grounding strap and the hardware to install it. This fits around the included hose which is conductive. This bag should include:

- Hose Static Strap (1x)

- Ground Wire Cable Assembly (1x)

- Stainless Steel M5 Lock Washer (1x)

- M5 Nylon Locking Nut (1x)

- M5x12mm Stainless Steel Socket Head Cap Screw (1x)

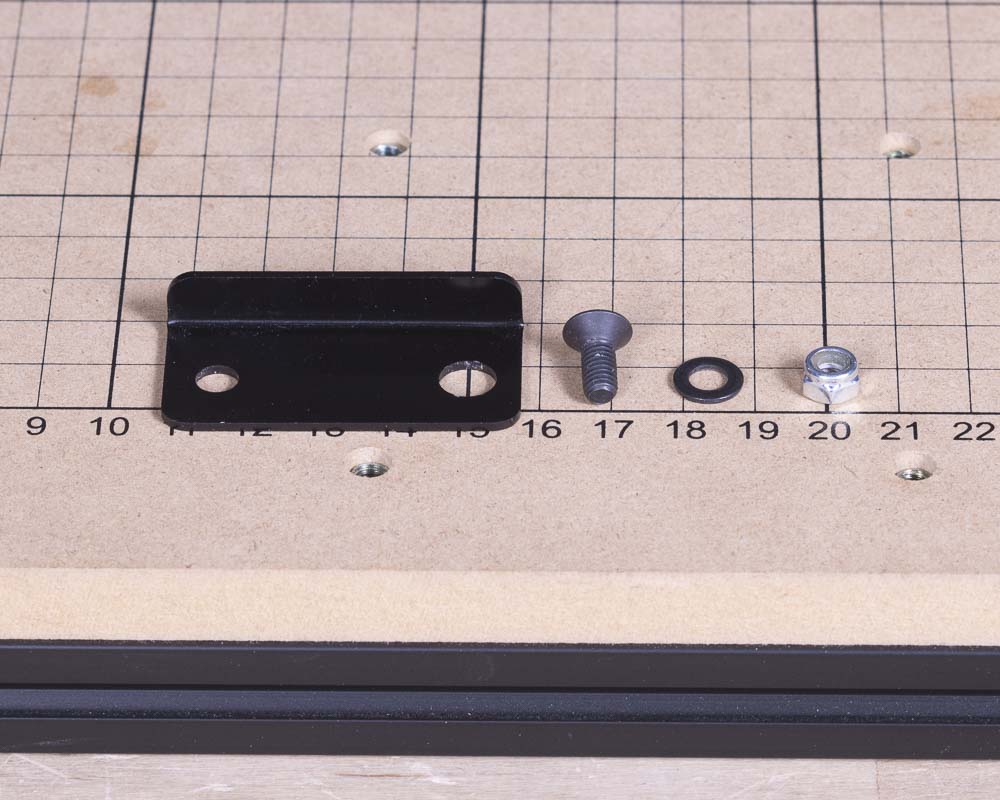

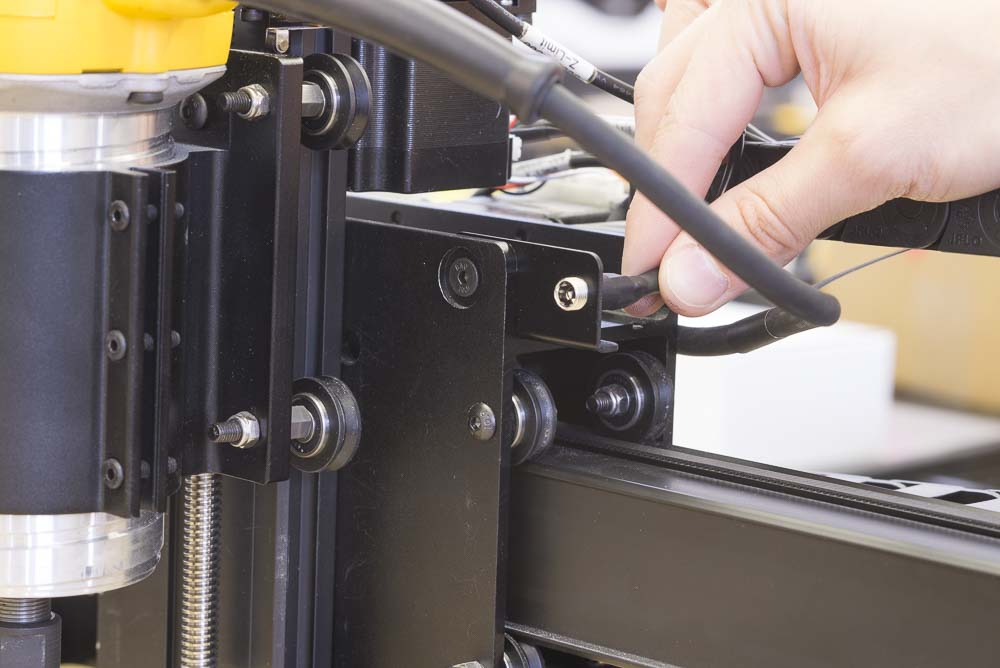

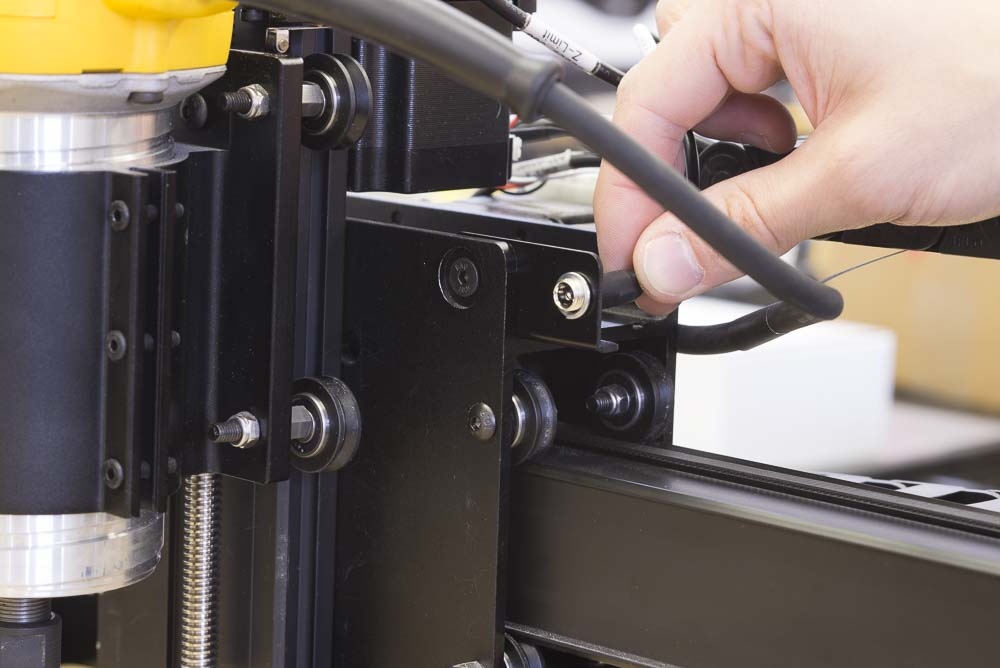

Z-Probe Relocation Kit

If you have a Z-probe connector mounted on your X-Carve’s x-axis carriage, you will use this kit to move the connector out of the way and allow for the dust shoe supports to be installed. In addition to the bracket, The bag of hardware should include:

- M5x12mm Flat Head Cap Screw (1x)

- M5 Washer (DIN125) (1x)

- M5 Nylon Locking Nut (1x)

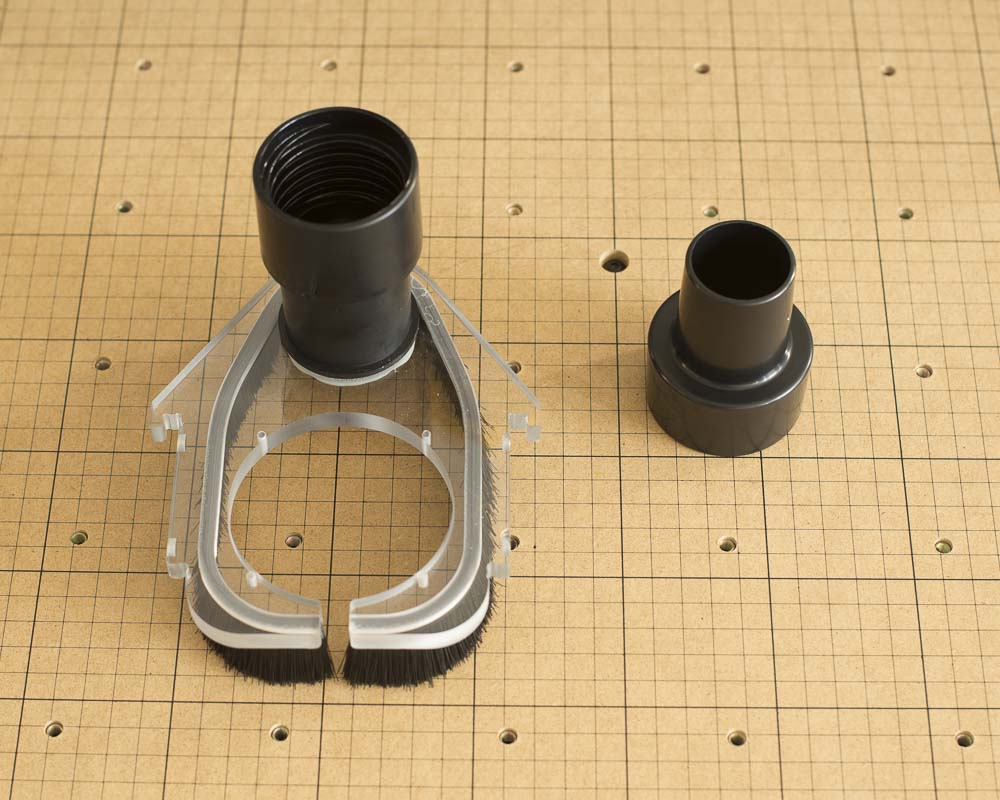

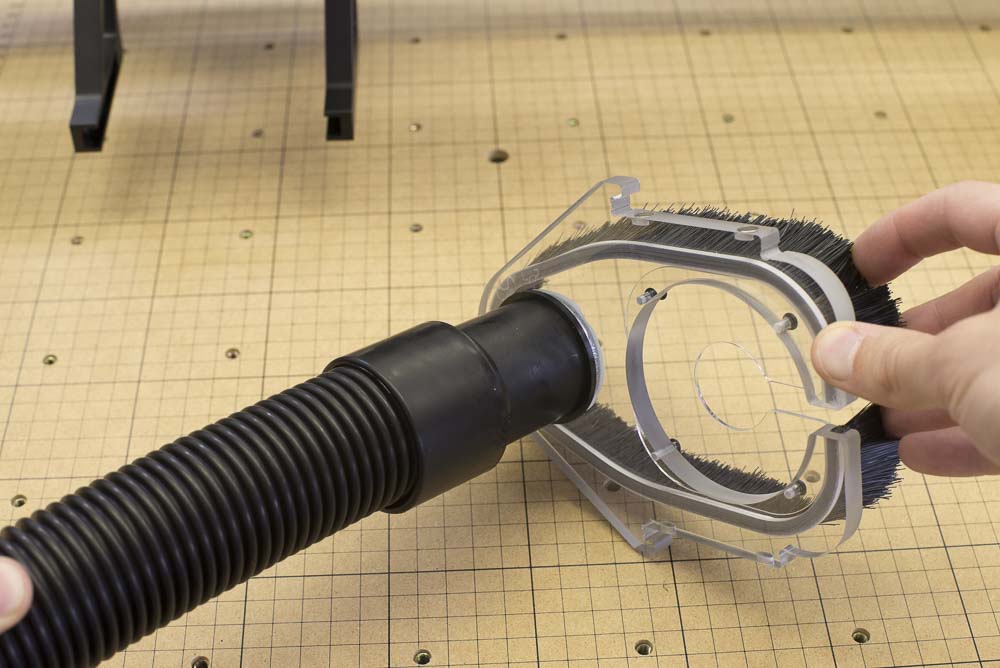

Dust Shoe and Hose adapter

These attach to either end of the hose. The hose fitting on the dust shoe is glued onto the clear plastic body and is not removable. The hose adapter (right) press-fits onto the vacuum side of the hose.

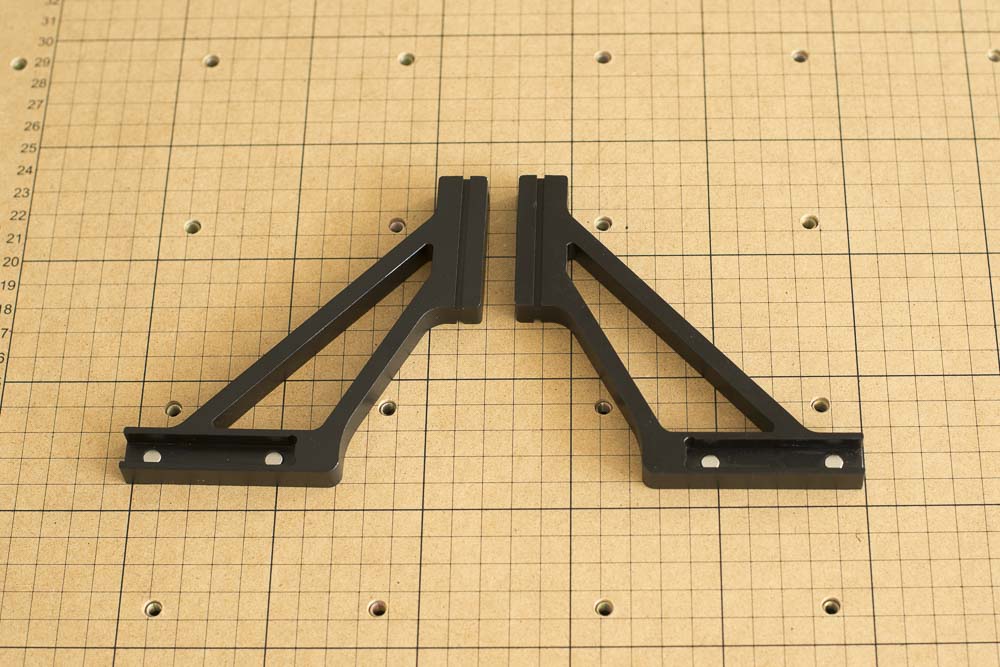

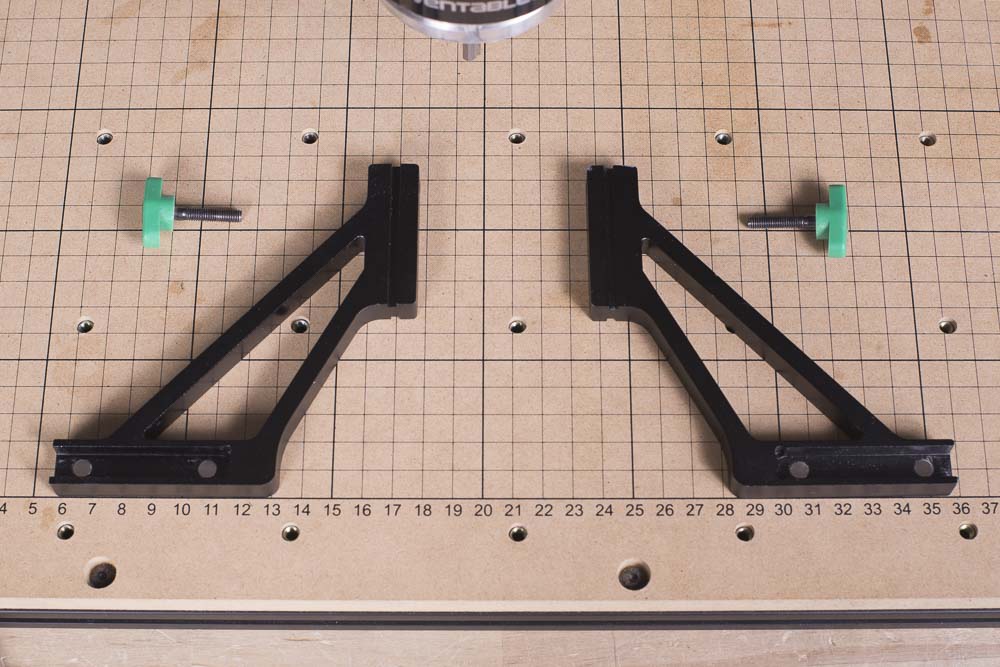

Dust Shoe Support Arms

These support arms hold the dust shoe in place when in use. The channels with embedded magnets serve to lock the dust shoe in place.

Arm Brackets

These brackets mount on either side of your X-Carve’s z-axis makerslide and have tracks for the adjustment of the dust shoe support Arms.

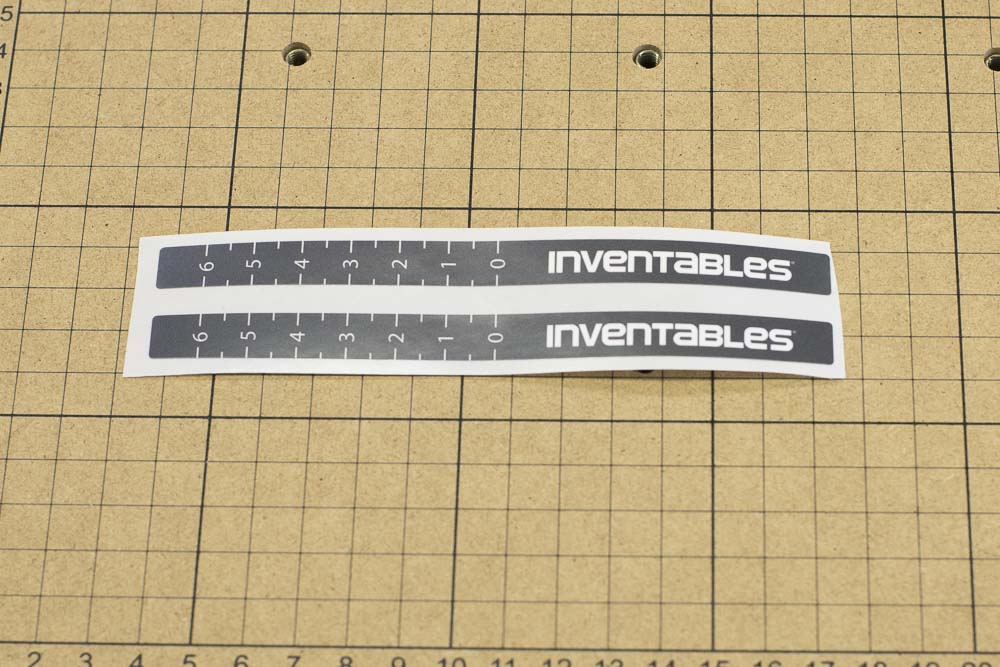

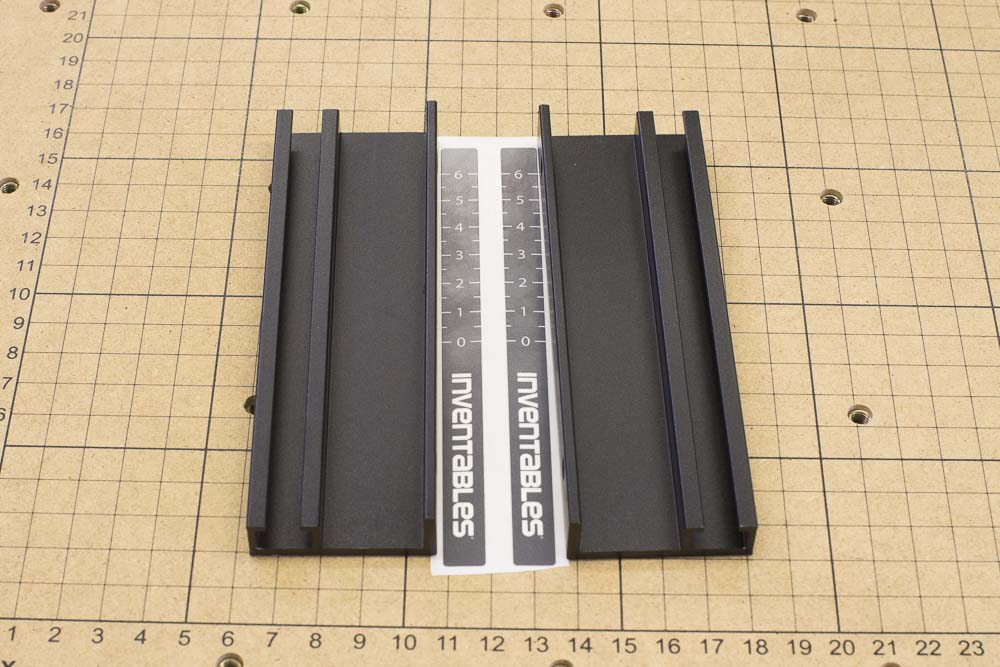

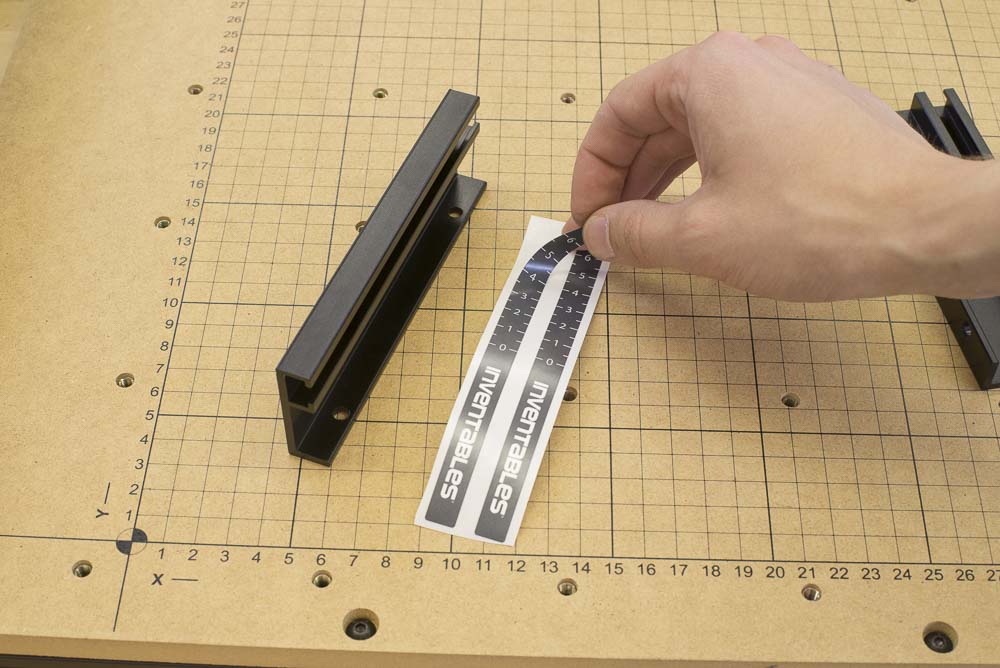

Dust Shoe Alignment Labels

These labels adhere to the side of each arm bracket and allow one to quickly align both support arms to each other.

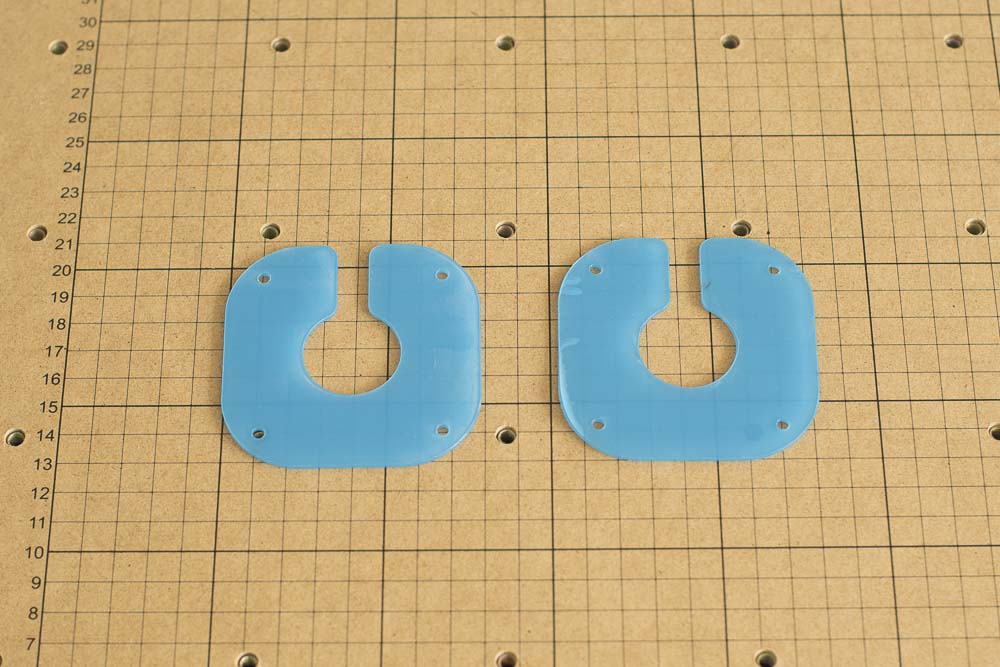

Spindle Insert Plate

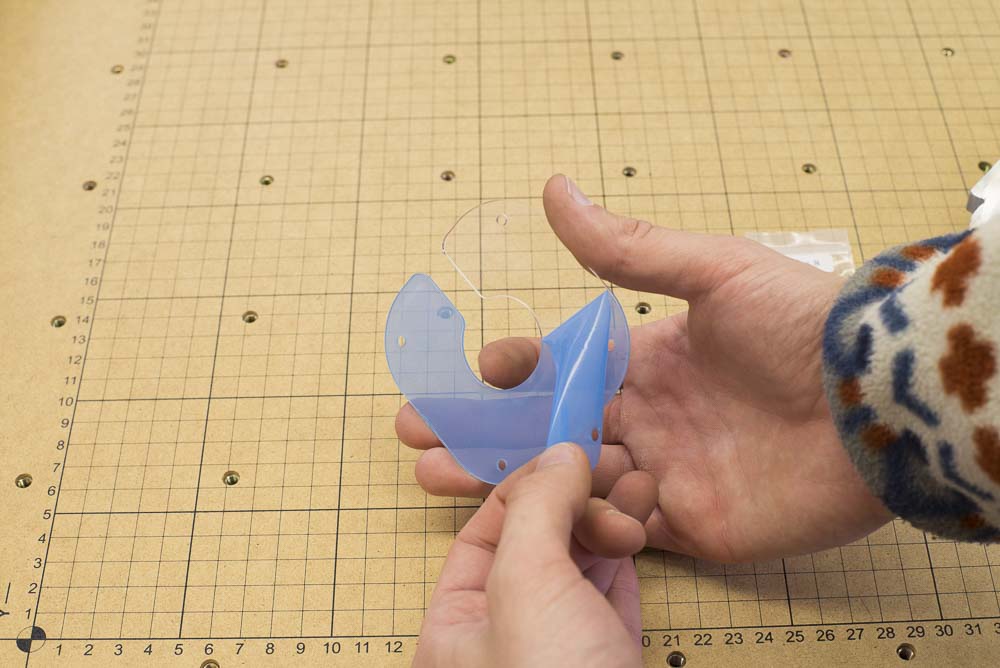

These replaceable inserts fit into the dust shoe to improve the vacuum seal of the assembly. They are pictured here with their removable plastic backing. We have included a spare insert in your kit, though only one is necessary for assembly.

Dust Shoe Hardware Kit

This kit includes the hardware necessary to attach the dust shoe supports to your machine. It should include the following hardware:

- M5x8mm Button Head Cap Screws (4x)

- M3x8mm Button Head Cap Screws (4x)

- T-Slot Nuts (4x)

- Clamp Thumb Screws (2x)

Build Instructions

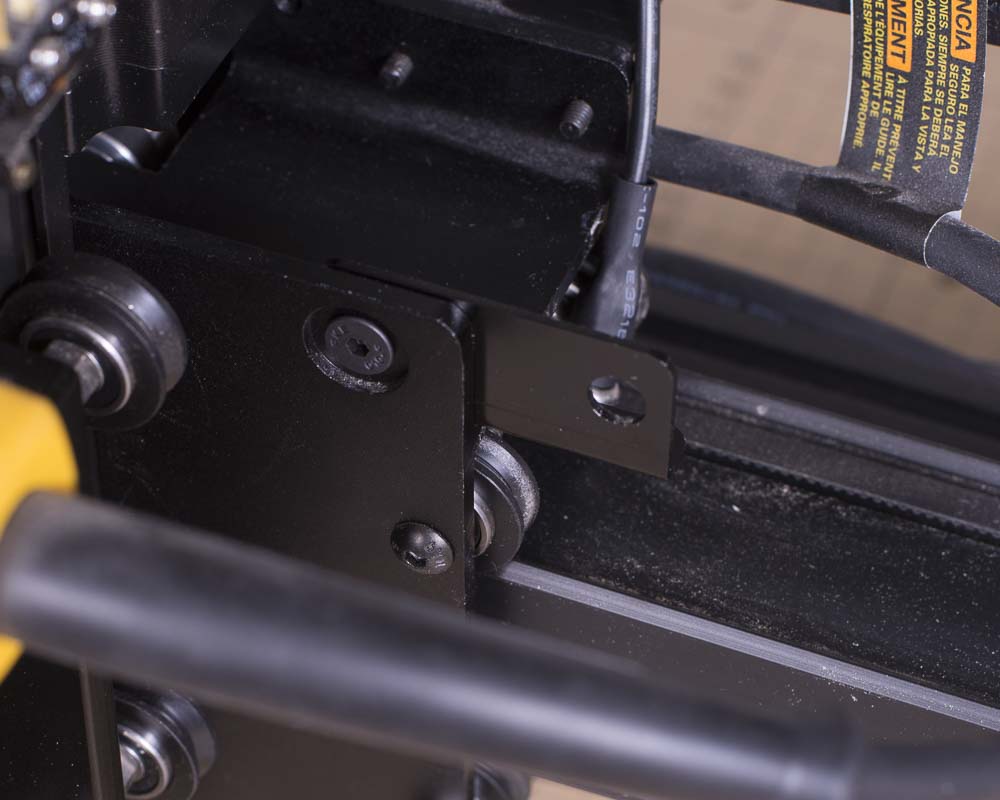

Z-Probe Relocation Bracket

If you have a z-probe connector attached to your x-axis carriage, You must install a relocation bracket for the connector so that it doesn’t interfere with the installation of the arm brackets. If you do not have a z-probe installed, you can skip this section. Start by gathering the relocation bracket, the M5x12mm flat head cap screw, the M5 washer, and the M5 nylon locking nut from the hardware bag.

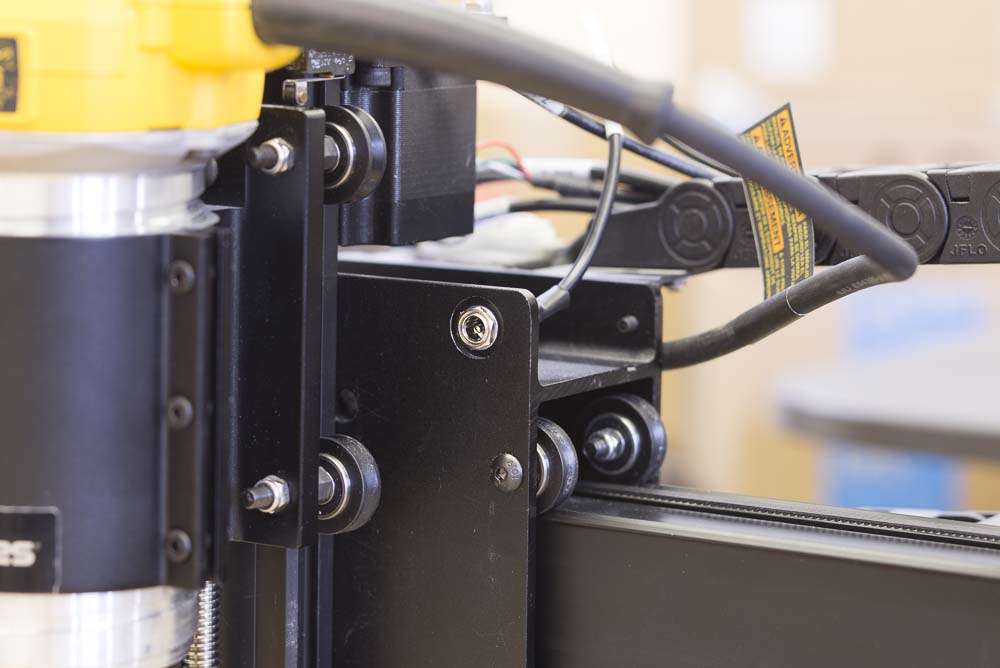

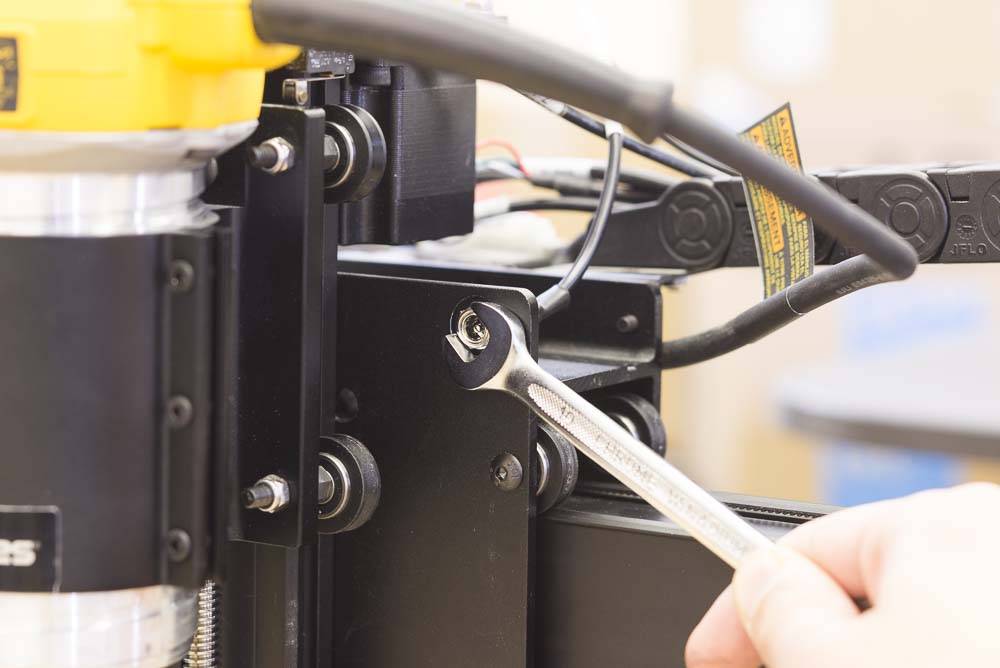

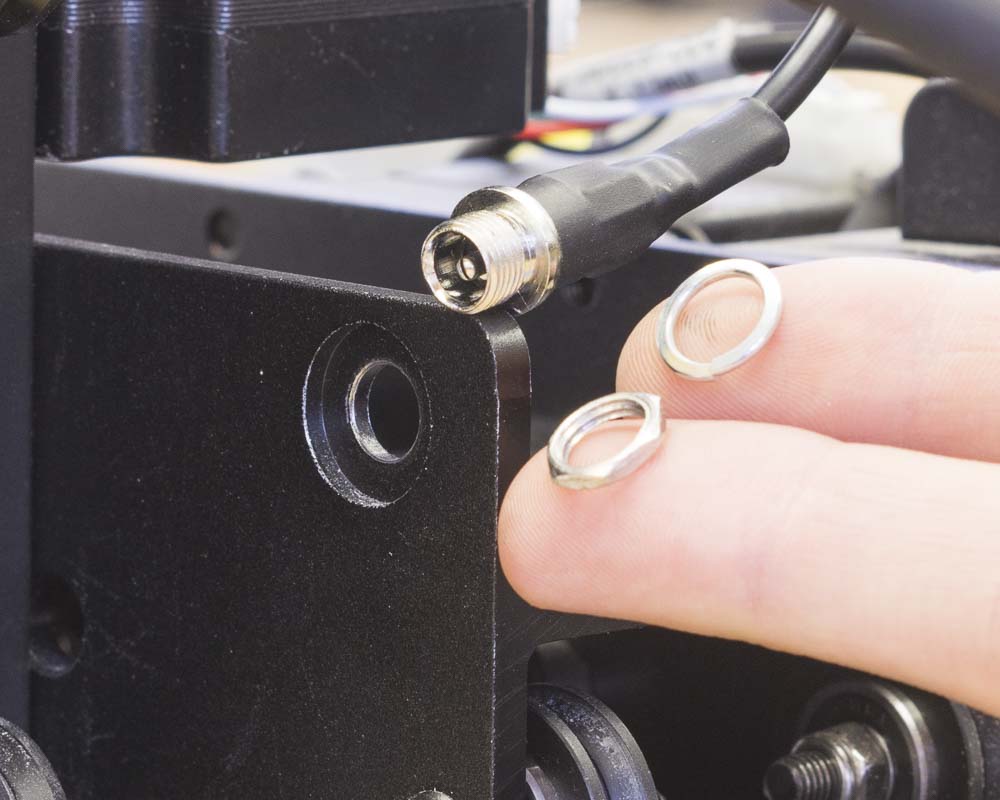

Remove the z-probe connector by loosening the thin retaining nut and split ring lock washer from the barrel of the connector. remove from the x-axis carriage.

Align the relocation bracket with the x-axis carriage so that the small hole on the bracket is aligned with the hole for the z-probe on the carriage. The “L” bend should be facing down to provide additional support for the bracket.

Insert the M5x12mm flat head screw into the front of the hole in the carriage. Put a washer on the screw, then secure the assembly with the M5 nylon locking nut.

Finally, use the thin retaining nut and split lock washer to re-install the z-probe connector on the relocation bracket.

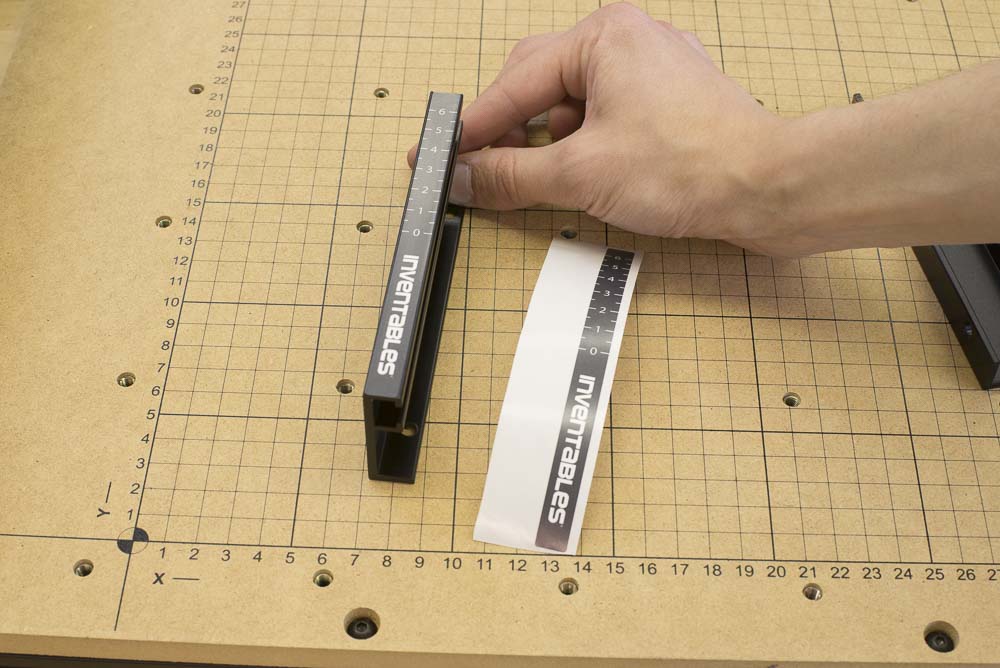

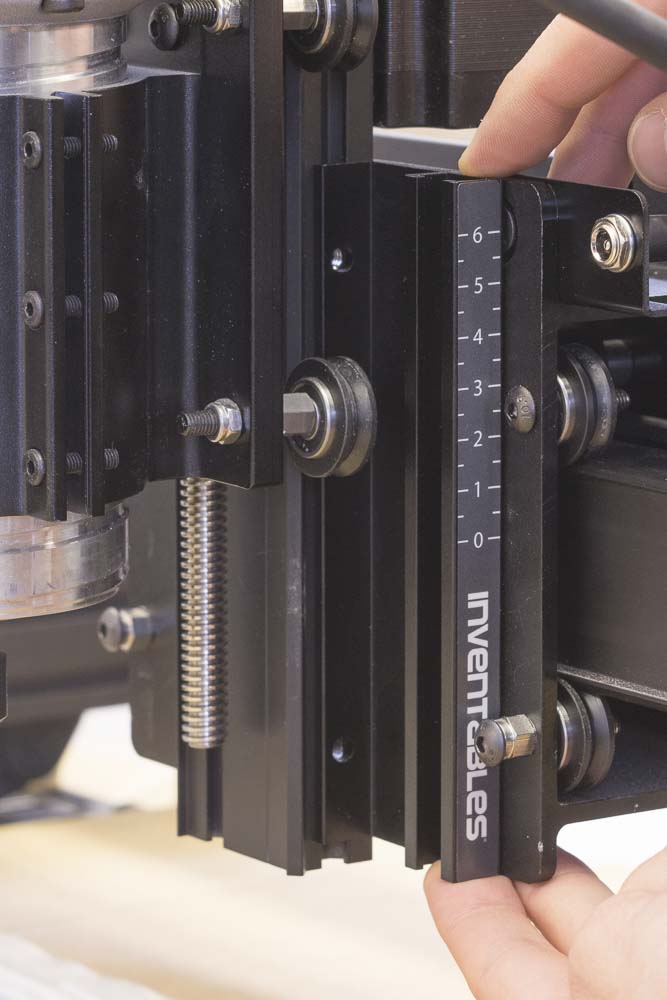

Install Labels On Arm Brackets

To assist in aligning the two dust shoe arms, we have included two adhesive labels to be mounted on the side of each arm bracket. Start by locating both brackets in your kit. They are identical, but will be mounted in a mirrored arrangement.

Begin by locating the two brackets and the two labels in your kit.

Peel the first decal off of the backing, then adhere it to the side of the left bracket as pictured.

Repeat this procedure for the right bracket. Note that the orientation of the right bracket should mirror the left.

The arm brackets can now be installed.

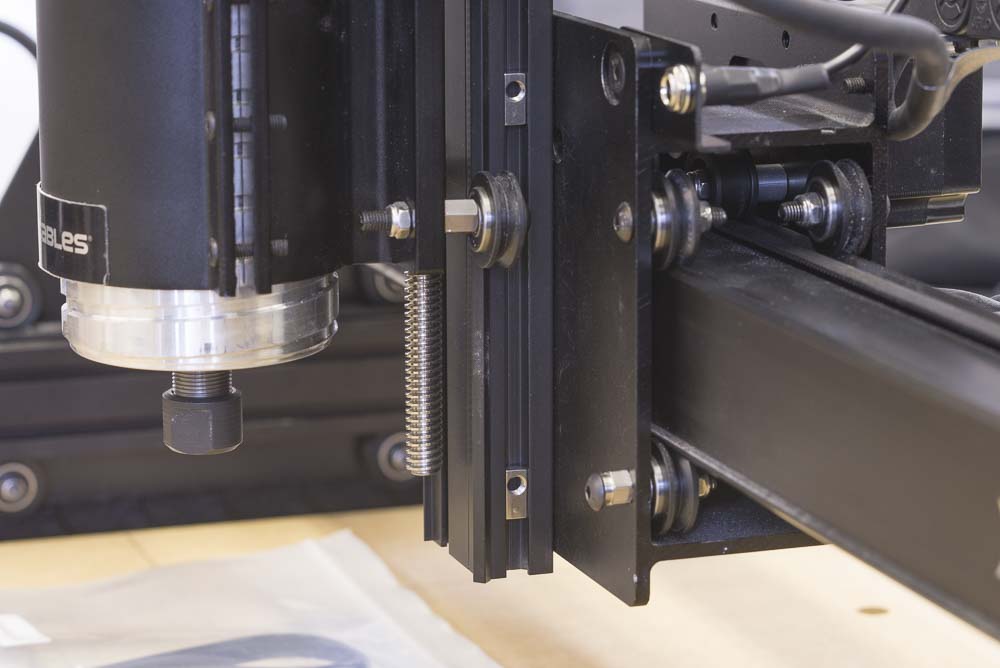

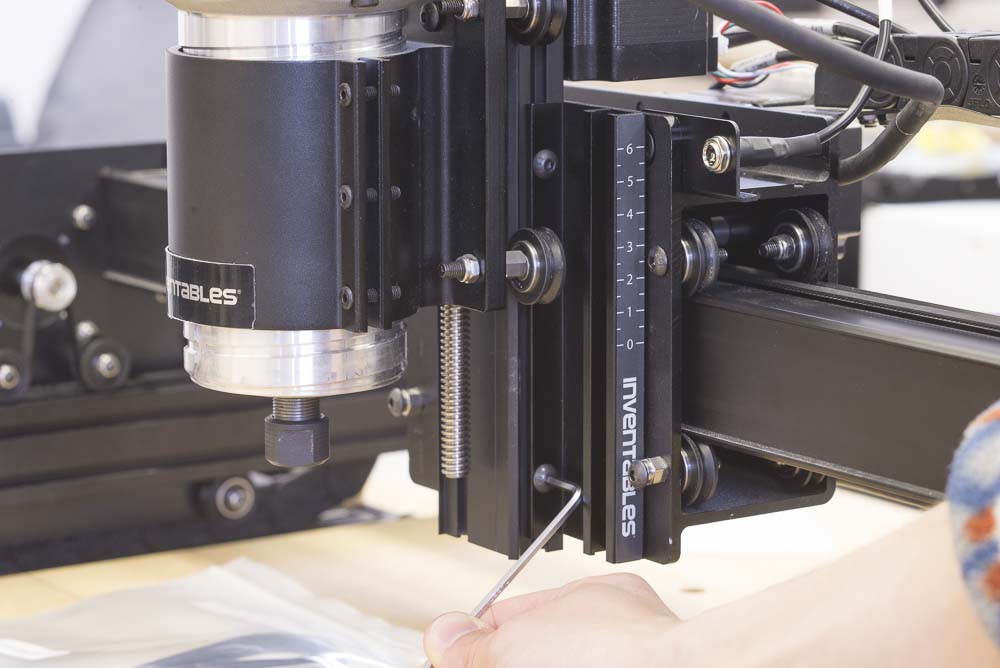

Install Arm Brackets

Begin by locating the four t-slot insertion nuts and M5x8mm button head cap screws in your dust shoe hardware kit. The t-slot nuts have a small, spring-loaded ball bearing to hold them in place while you align them with the brackets. There are two for each side of your z-axis makerslide.

Insert two t-slot insertion nuts into either side of your z-axis makerslide.

Roughly space the two t-slot nuts, and use the holes in the sides of the arm brackets to align them accurately. You can use the long end of a hex key to move them around. The bottom of the arm brackets should be flush with the bottom of the x-axis carriage. You may have to pivot the brackets around the v-wheels to get them to fit.

Align the Arm Bracket so that the Inventables Logo is facing down, then secure each bracket to the makerslide with two M5x8mm button head cap screws.

Install the other bracket using the same technique.

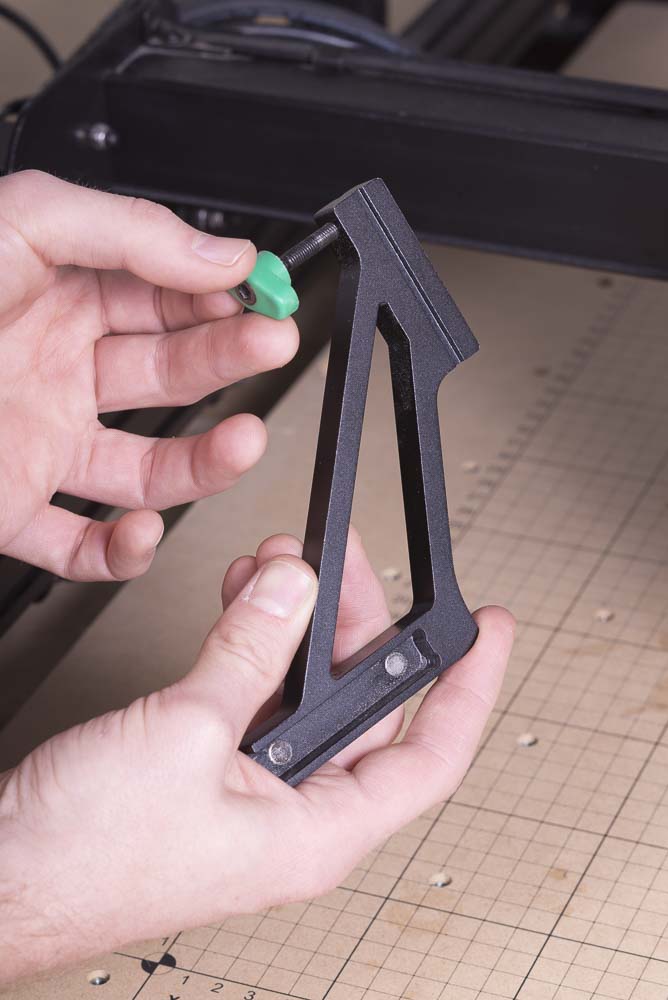

Install Dust Shoe Arms

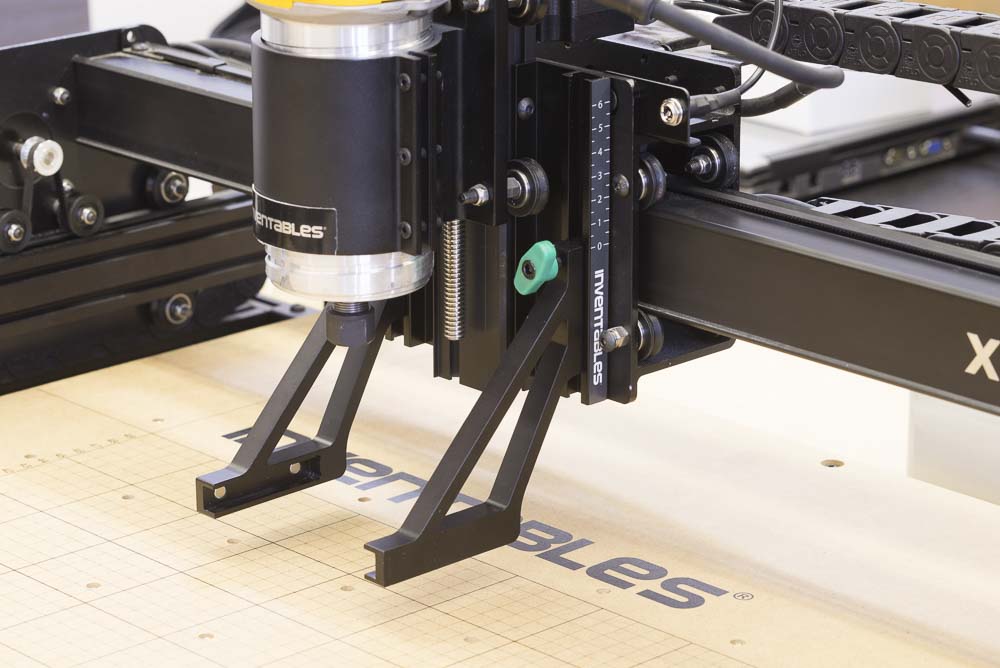

Locate the two dust shoe arms as well as the clamp screws that go with them. Note that these are mirrored parts and not interchangeable with one another. Note the small magnets on the bottom slot of each arm. These align with the magnets in the dust shoe and help to keep it in place.

Thread in the clamp screws into each arm. Thread them far enough in that the end of the screw almost comes through the other side of the threaded hole. This will make them easier to install.

Slide both arms into the slots on the brackets. Make sure that the channels in each arm are facing each other.

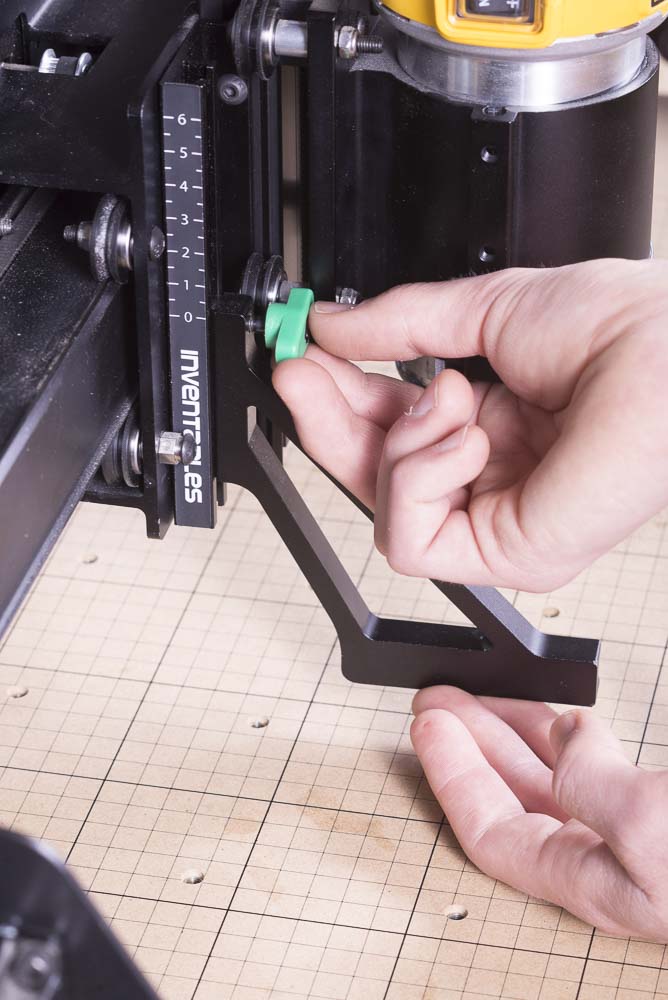

Secure each arm with the included green clamping screw until snug

Install Spindle Insert Plate

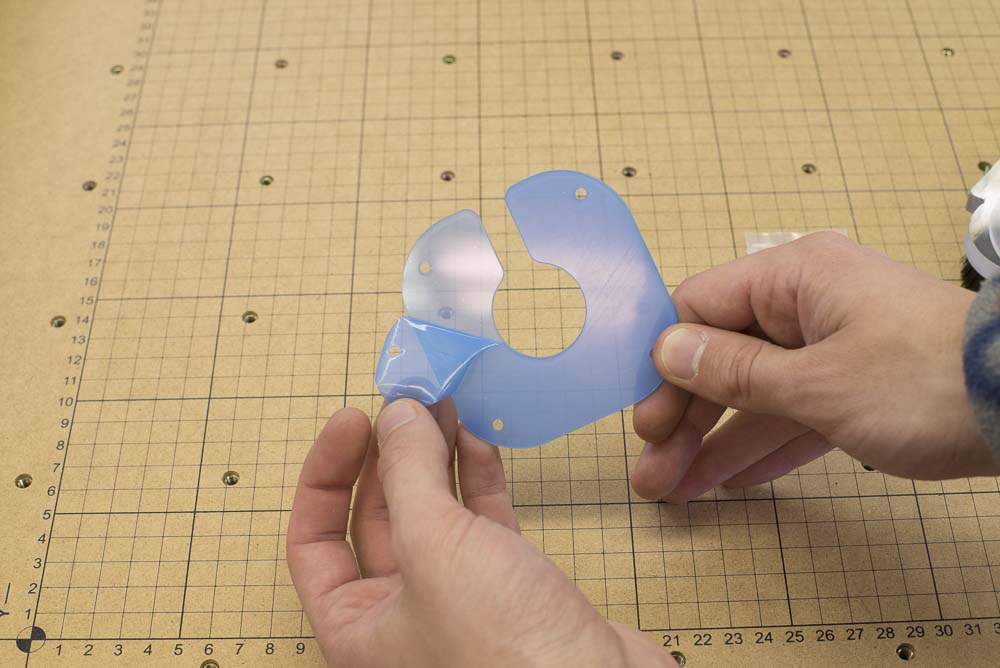

For your dust shoe to operate properly, you will need to install a small plastic insert on the underside to maintain the proper suction during cutting. This is designed to be replaceable so that damage from the bit, collisions, etc. is relatively limited. Begin by peeling the protective backing off of each side of the insert.

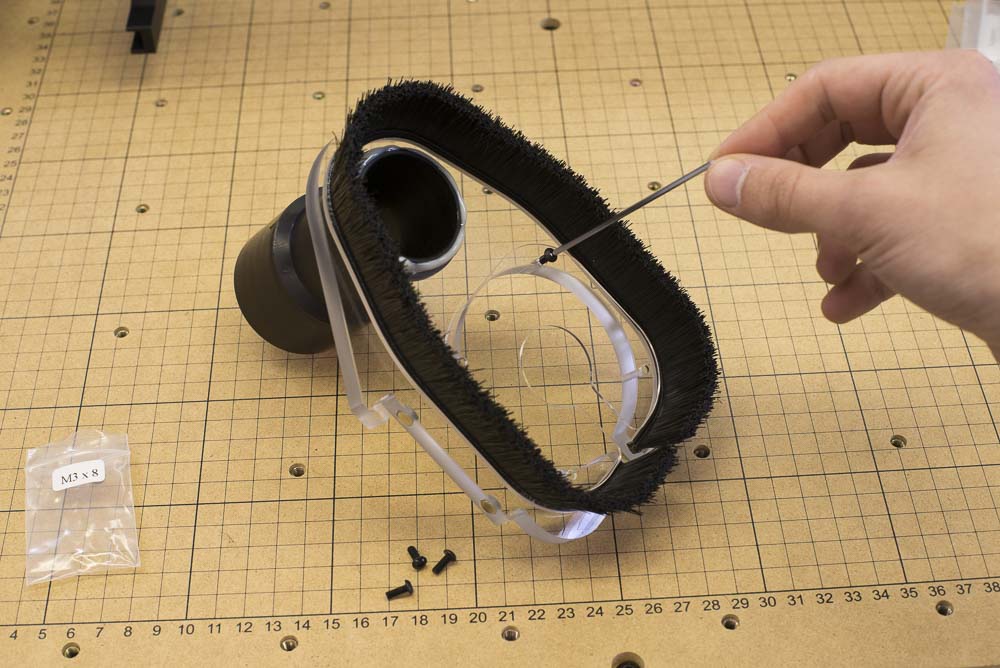

Using four M3x8mm button head cap screws and a 2mm hex key, secure the insert to the shoe. The holes for the screws are already drilled and tapped. Take care to avoid cross-threading or stripping the holes.

Adjust the arm height as necessary then slide the dust shoe onto the slots in the two support arms. If the dust shoe doesn’t slide in easily, try loosening one of the arms slightly then tightening it when once the dust shoe is inserted. You’ll attach the hose to the fitting in a later step.

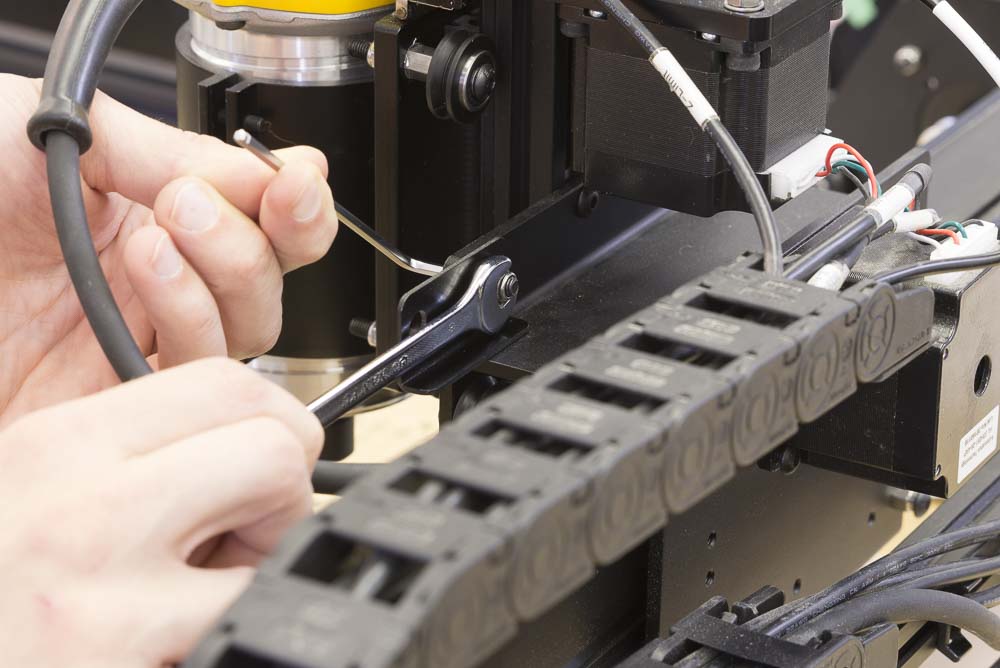

Install Hose Support Pole

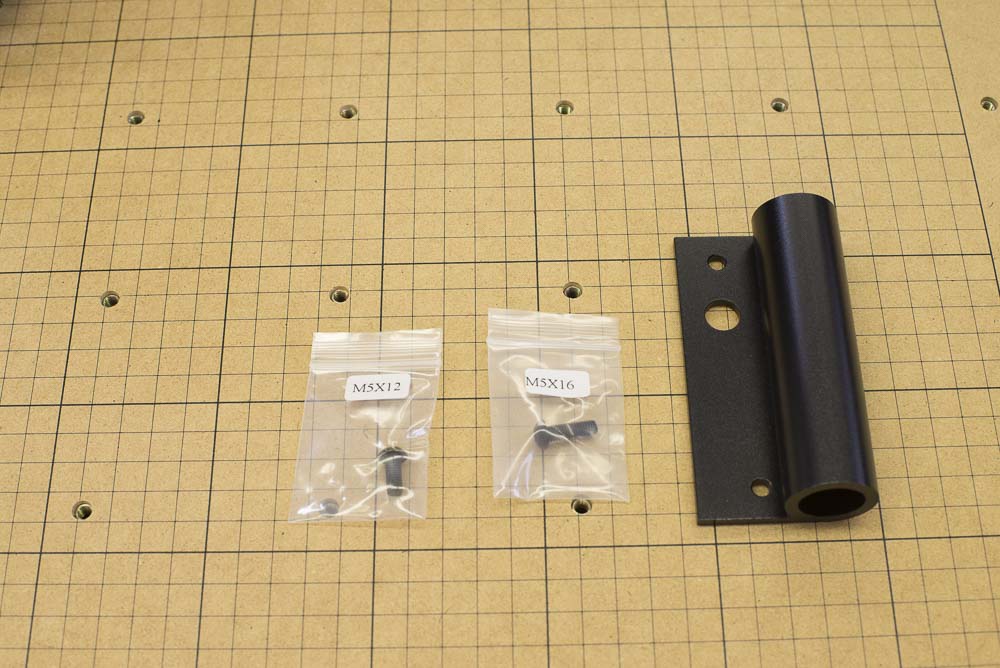

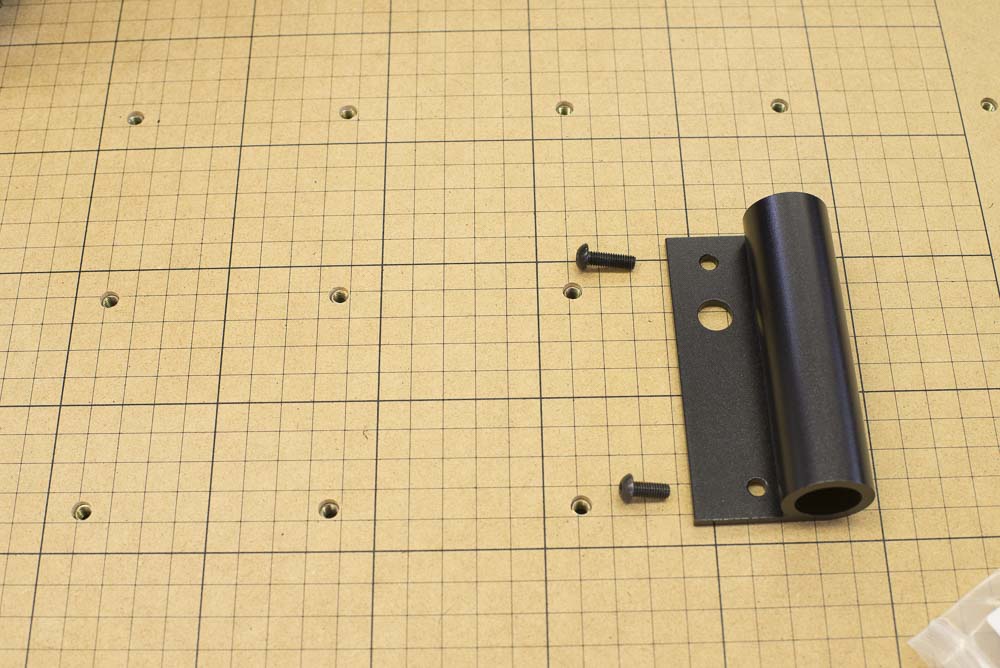

To suspend the vacuum hose, you’ll need to install the support pole on the lower right corner of the machine. Begin by locating the pole mounting bracket, the M5x16mm button head cap screw and the M5x12mm button head cap screw from your support hardware kit.

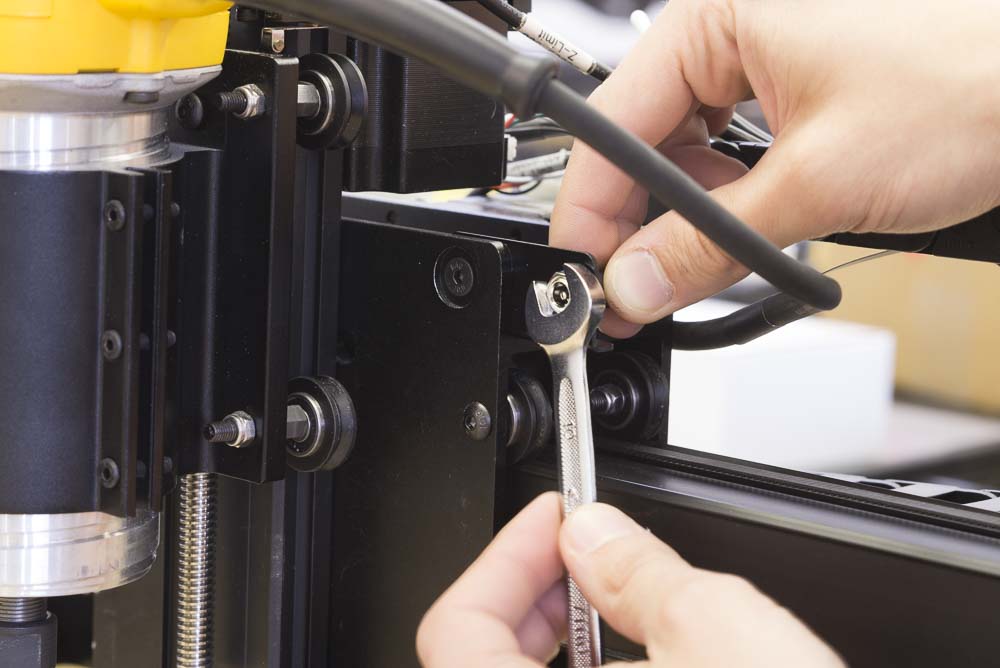

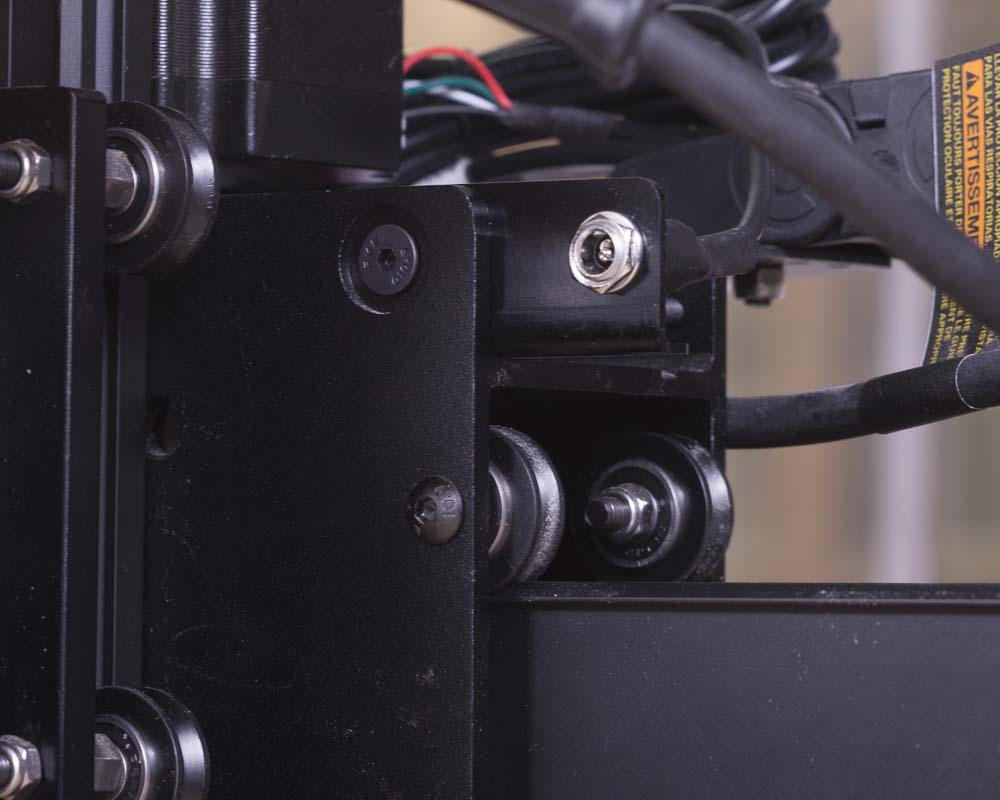

Use a 3mm hex key to remove both the top and the bottom right screw on the lower-right makerslide end plate.

Align the bracket with the holes on the makerslide end plate. Note that the large hole is designed to clear the head of the middle button head cap screw.

Secure the top part of the bracket with the M5x16mm button head cap screw, followed by an M5x12mm button head cap screw on the bottom. You may have to re-align the t-slot nut for the bottom screw.

Now you can set up the support pole itself. First, Locate the two poles that make up the support arm.

Locate the five hooks that mount onto the poles and the five M5x8mm socket head cap screws that hold them in place. The screws thread into the hole on each hook to secure the hooks to the poles.

Insert the straight section of the pole into the bracket so that the tapered section is pointing up. The pole should be free to turn in the bracket so that it can swing back and forth during use. Slide a hook onto the pole so that the end of the hook is pointing clockwise if looking from above. Align this first hook closer to the bottom of the pole. Use a 4mm hex key to secure the hook in place.

This hook will remain empty during use, but will serve as a temporary clip for the dust shoe to keep it out of the way when setting up a carve.

Add a second clamp facing the same direction. This should be set at 90-120º counter-clockwise from the first clamp.

Locate the angled pole and the three remaining hooks. Arrange the hooks as shown.

Attach the angled pole onto the straight pole, sliding it into place.

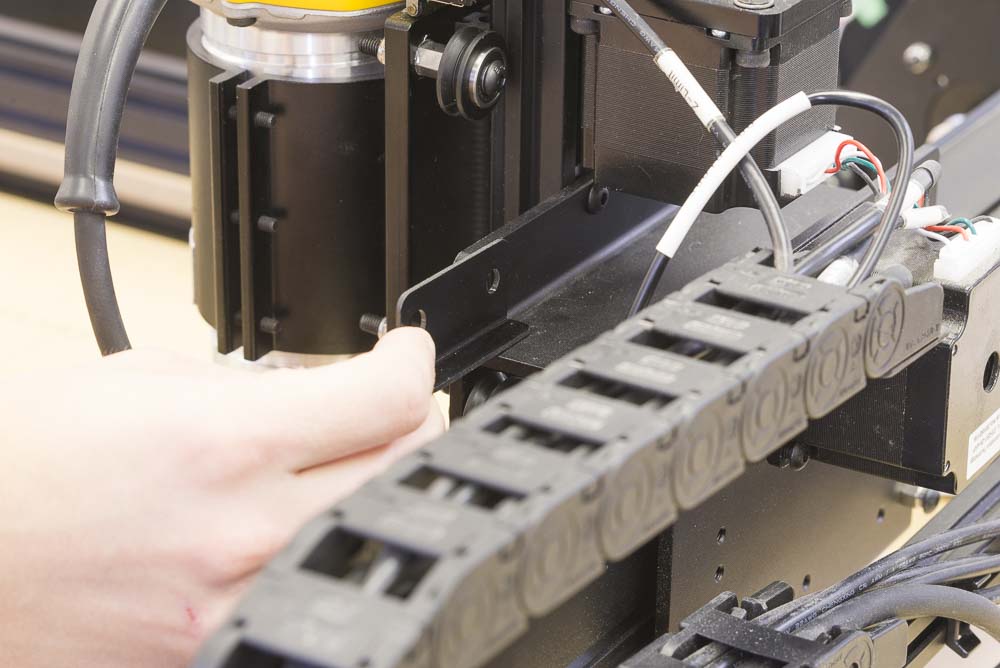

Attach the dust shoe to one end of the hose, and the hose adapter to the other. The dust shoe fitting has a left-hand thread, so it’s a “lefty-tighty” configuration. The adapter is a simple press-fit.

Clip the hose in place so that the dust shoe has a free range of motion across the entire area of the bed.

You can also test the clip for the dust shoe when it’s not in use.

Install Static Dissipating Band

The plastic hose included with your kit is made of a conductive plastic designed to dissipate static charge built up from material moving through the hose. We recommend grounding the hose to reduce the risk of electrostatic discharge, which can start fires and damage electronics. We include a grounding wire with an aluminum band which can be connected to an electrical ground connection, outlet cover screw, or cold water pipe. First, locate the grounding wire, band, bolt with washer, and nut.

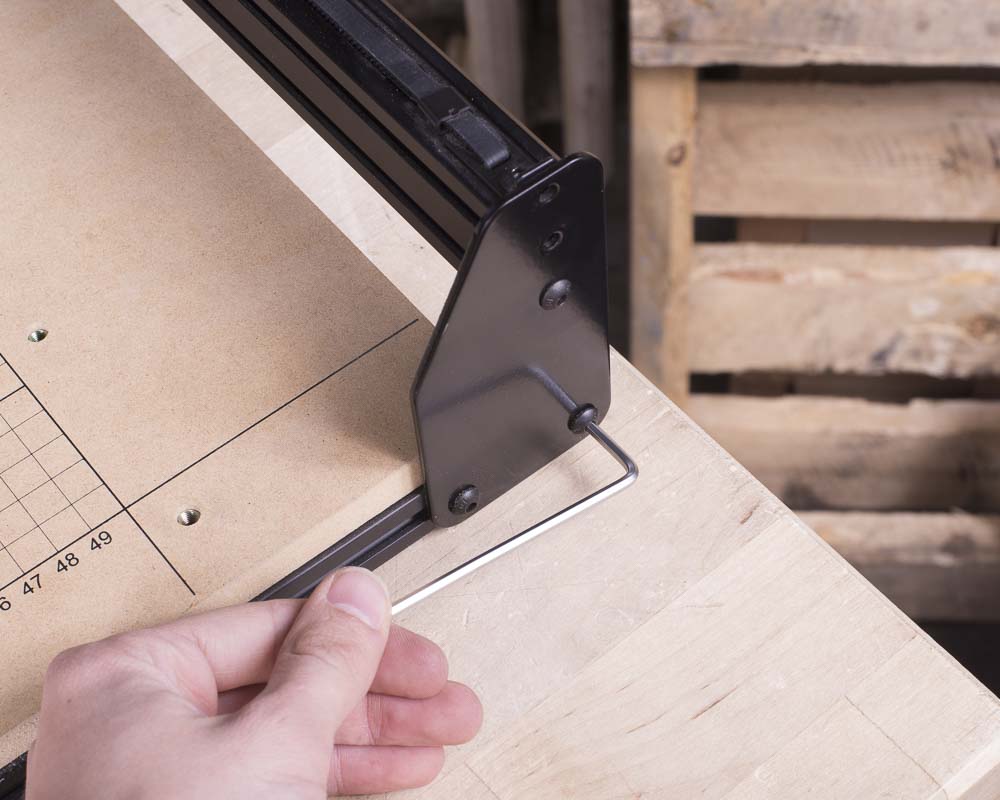

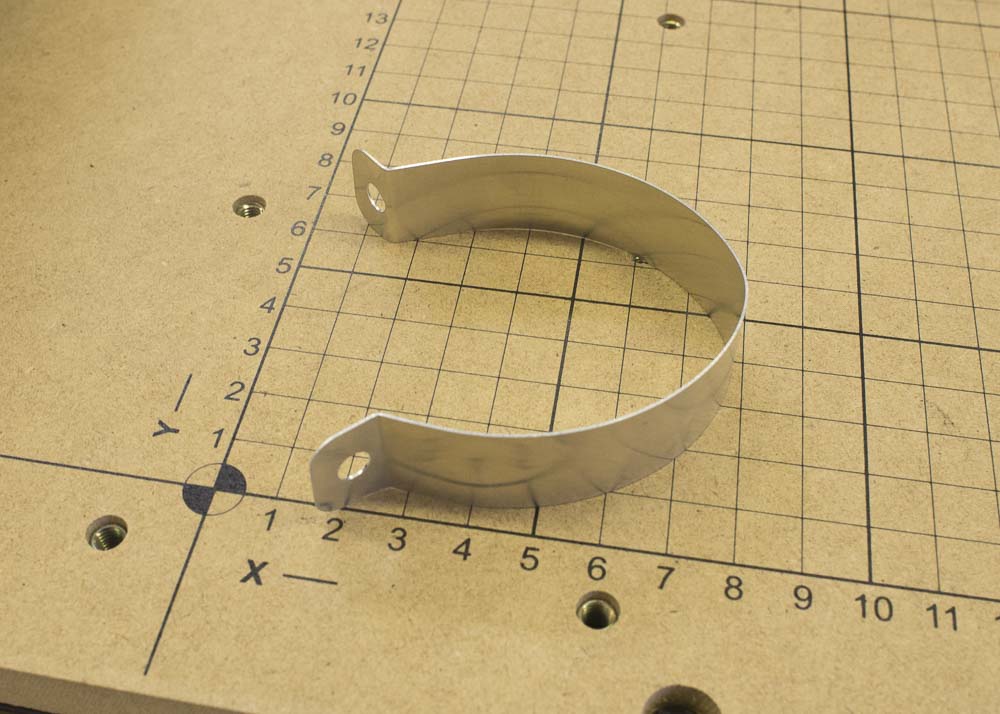

Pre-form the aluminum strap as pictured below. This can be done using the edge of your wasteboard.

Bend the aluminum strap around the hose. Insert the bolt through the round connector on the grounding wire, then insert it through both holes on the aluminum band. Use the washer and nut to secure the band in place. Once the band is installed, you can attach the other end of the wire to a ground connection like a switch plate cover screw or cold water pipe.

Setup and Usage

Now that you have the dust shoe and hose installed, it’s time to set up your workspace and run a job.

Attach Hose to Vacuum

With the adapter installed, attach the end of the dust collection hose to your vacuum. This is a standard connection so most any standard Shop-Vac-style connection. If you haven’t done so already, make sure that the wire from the aluminum grounding strap has been attached to a outlet cover screw, cold water pipe, or other electrical earth.

Check Homing Switch Positions

If you have homing switches on your machine, check to ensure that the dust shoe/dust shoe arms don’t run into the Y axis end plates of the machine before the X/Y axes hit their respective actuators. If there seems to be interference, move the actuator bolts until there’s no interference. You’ll want to power off your machine and disconnect it from the controller before moving your axes by hand.

Easel Setup

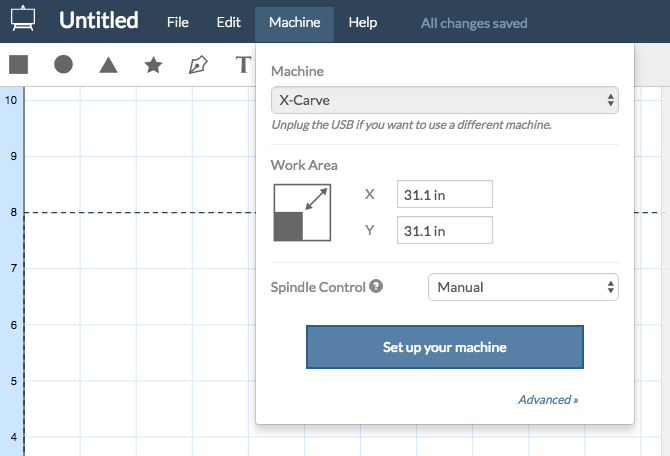

If you’ll be using Easel for carving, you’ll want to take your machine through the setup process again to add the dust collection system to the carve dialog. First, connect your machine and open up Easel. Go to ‘Machine->Set up your machine’

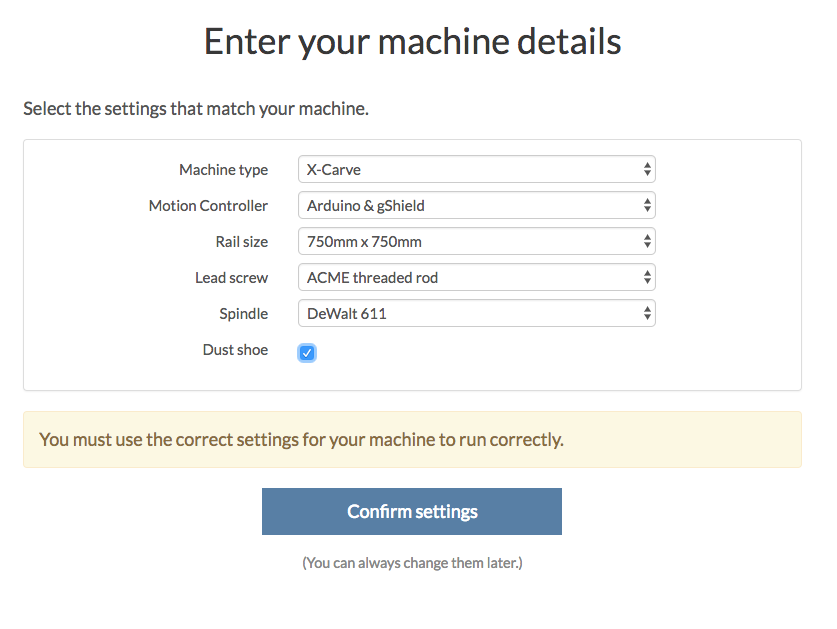

Make sure that you check the box marked ‘Dust shoe’ on the initial setup page.

You can then proceed through the machine setup normally.

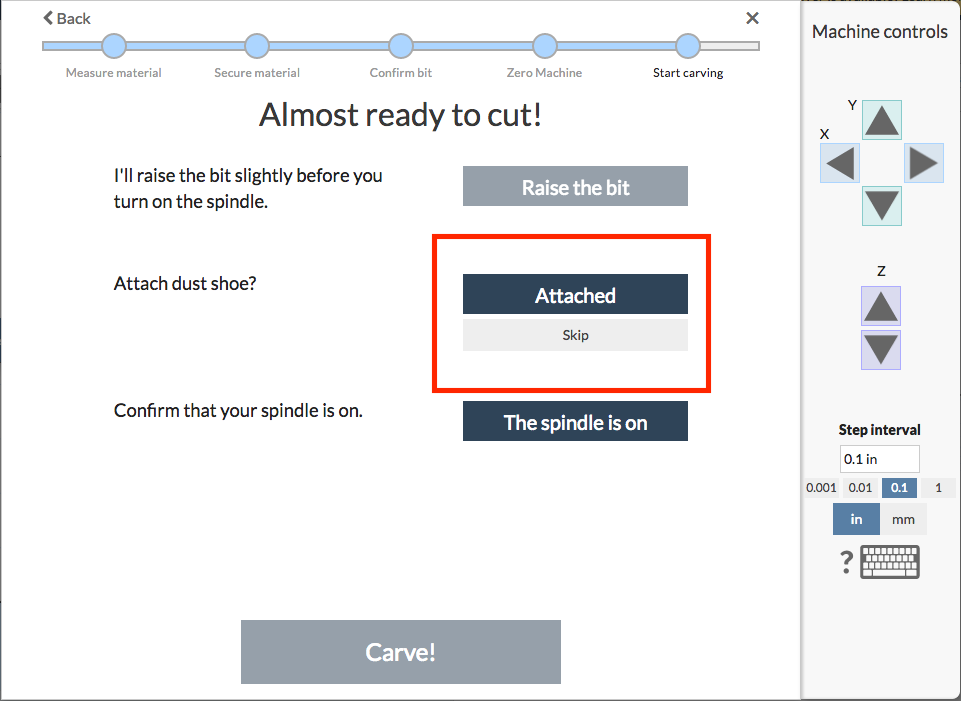

When you go to carve, you’ll be presented with a prompt just before turning on the spindle to attach the dust shoe.

The process for setting up your job for a carve with the dust collection system is covered below. You will be prompted to do these steps when you click ‘Carve’ in Easel.

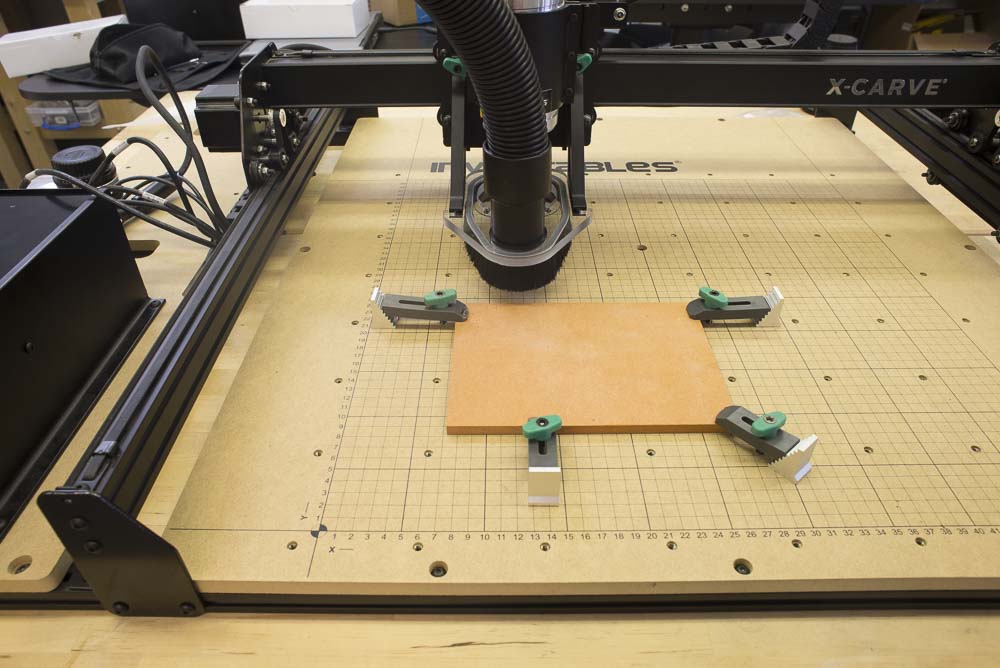

Clamp Your Material

Start with your dust shoe detached and secured out of the way. Choose a convenient spot on your wasteboard to mount your material. You can use double-sided tape or step-clamps to hold the material down. Double-sided tape is ideal for working with the dust collection system as you don’t have to worry about the dust shoe hitting clamps. If you’re using step clamps, you’ll want to make sure that they don’t protrude too far above the top of the material to avoid collisions.

The Clamp Set for 3D Carving comes with a number of step block and bolt sizes. Choose the shortest possible clamp for your material.

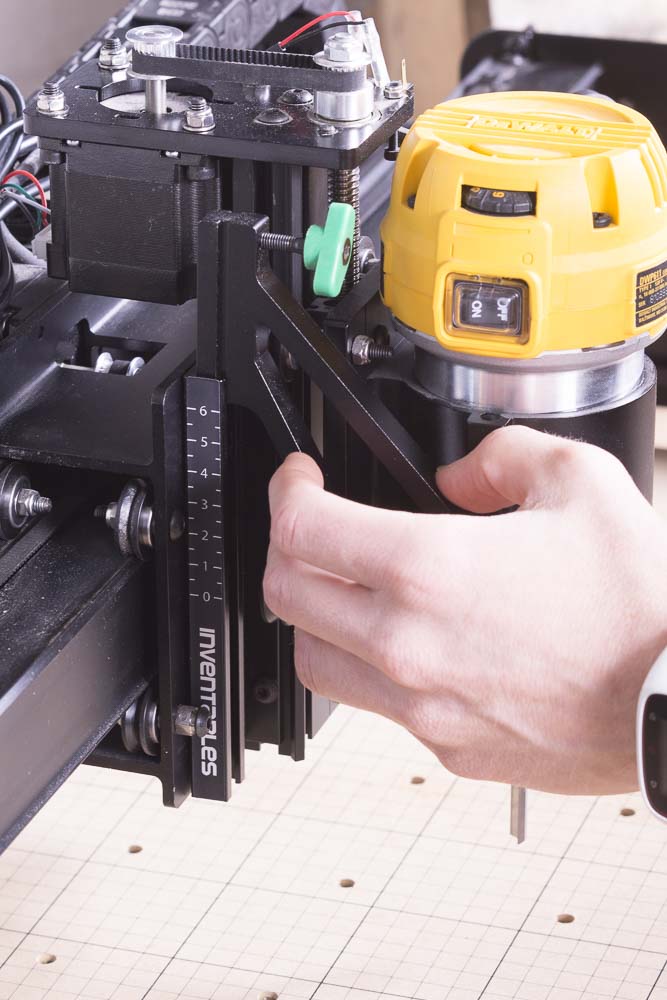

Insert Bit

The dust shoe will make the the collet nut inaccessible, so it’s necessary to install the bit before sliding the shoe into place. Take care not to hit the dust shoe arms on either side of the spindle when securing the bit.

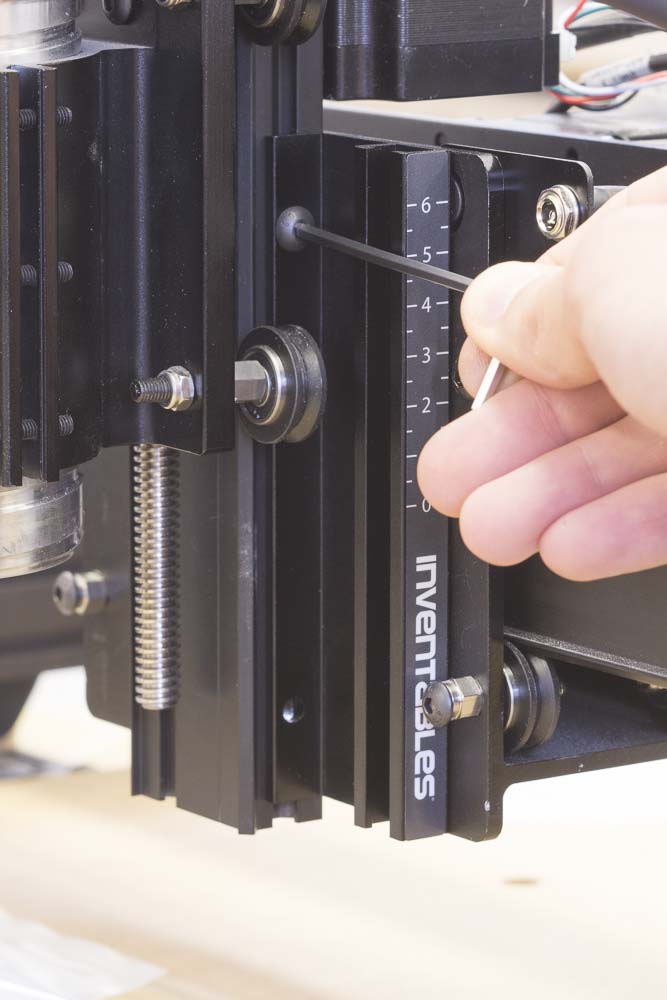

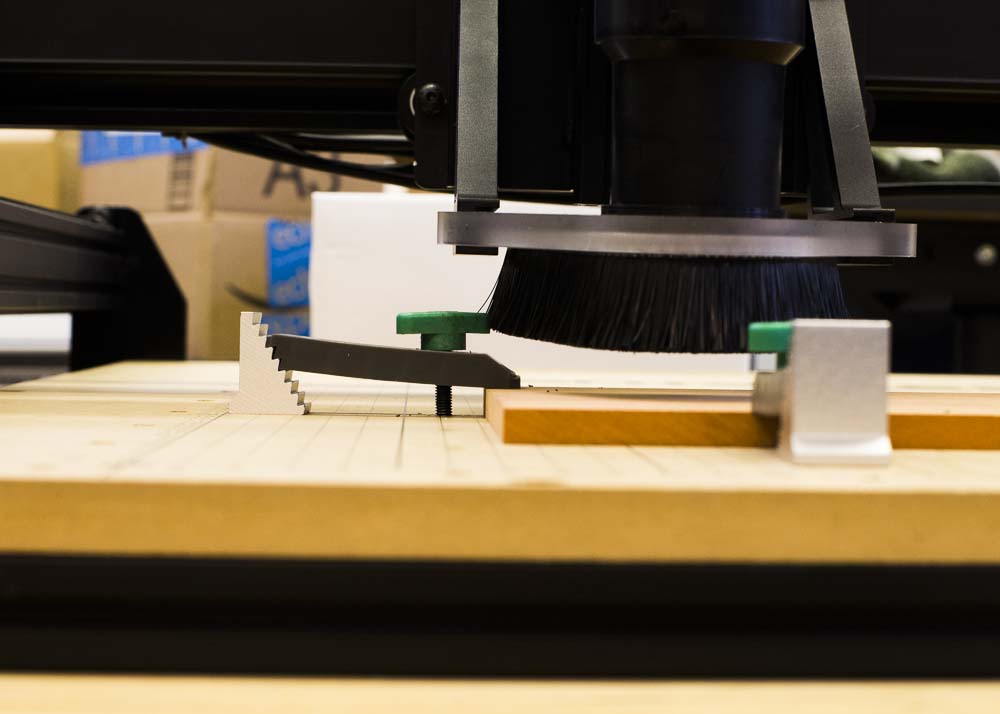

Insert and Adjust Dust Shoe

First, loosen the clamp screws on both dust shoe arms and raise them to the top of their slots. Insert the dust shoe into the slots at the bottom of the arms and ensure that it ‘clicks’ into place with the embedded magnets. If you’re having trouble inserting the dust shoe, try loosening one of the dust shoe arms, inserting the dust shoe, then re-tightening the arm.

You can now adjust the height of the dust shoe relative to the top of the material to be cut and the clamps if you’re using them. You’ll want to make sure that the brush is touching the top of the material or is as close as possible. More importantly, you’ll want to make sure that the acrylic shoe clears the tops of any clamps you have installed. It’s okay if the brush touches the clamps during the course of a carve. You can check this clearance by visual inspection of the work area, or jogging the spindle over the tallest clamp and physically checking the clearance of the shoe.

Before securing the clamp arms, use the scales on either side of the arm mounting brackets to make sure that both sides are roughly at the same height. Use the green clamp screws to secure the arms in place.

You can now turn your vacuum on and run your carve.

Next Step: Computer Setup